Challenge

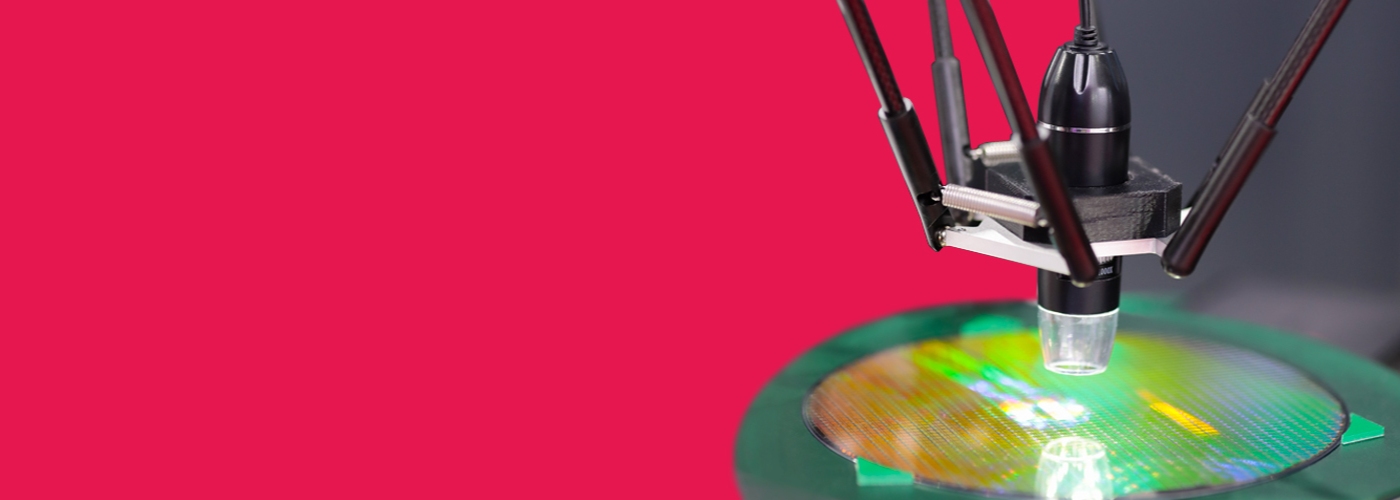

An OEM of Automated Optical Inspection (AOI) equipment needed automation software for its industry-leading AOI equipment. The OEM required a complete software automation stack to control its advanced AOI equipment while strictly adhering to SEMI standards. The OEM sought a strategic engineering partner who could manage the entire spectrum of equipment control and factory host connectivity, allowing its teams to focus their expertise on product innovation.

Solution

Quest Global designed and delivered a custom equipment control solution with factory host communication and data acquisition capabilities leveraging our 2+ decades of industry expertise and in-depth knowledge of SEMI standards. The team

Developed a comprehensive SEMI standards-compliant architecture based on a thorough analysis of the client's AOI equipment configuration and requirements. The architecture integrated both hardware control capabilities and factory automation needs into a unified solution

Implemented equipment automation and factory host communication applying SEMI E4, E5, E30, E37, E39, E40, E58, E84, E87, E90, Stream 12, G84, E116, E58, and E94 standards

Created fully SEMI standards-compliant Interface A implementation adhering to SEMI E120, E121, E125, E128, E132, E134, E138, and E147 standards. Implemented E164-compliant metadata fusion with advanced security controls and established high-performance data collection systems exceeding SEMATECH specifications

Created SEMI E95-compliant user interfaces with critical equipment control functions, including job and recipe management, maintenance scheduling, diagnostics, monitoring systems, and real-time material tracking

Developed support for both 32-bit and 64-bit operating systems

Architected and implemented a comprehensive testing and test automation suite

- Executed ISMI and SAT test cases with ECCE client validation

- Implemented automated testing frameworks with CCS Envoy validation

Integrated the solution with hardware at the customer site and followed it with fab acceptance support

Executed deployment through local-global implementation model with 15% onsite and 85% offshore development with comprehensive post-release 24x7 support

Results – at a glance

Enabled full focus on hardware development and optimization for the client, taking complete software development ownership

Achieved successful market entry while maintaining R&D efficiency

Enabled high-volume, real-time data collection without performance impact

Achieved complete SEMI standards compliance

Passed global Factory Acceptance Tests on first submission

Reduced equipment qualification timelines at customer facilities

Maintained consistent software performance across worldwide installations